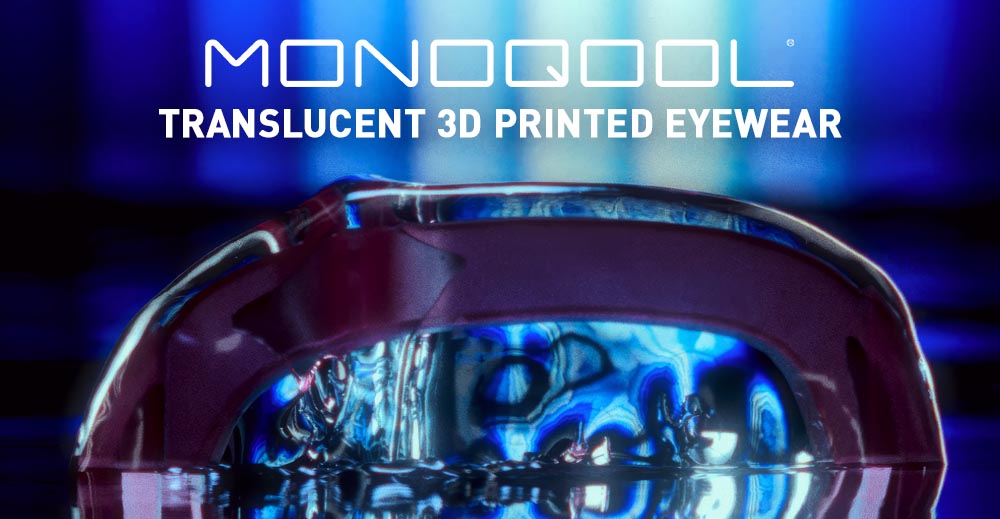

Monoqool launches new translucent 3D printing with eco-friendly manufacturing process

3D-printed glasses have in recent years been one of the fastest-growing categories of eyewear. 3D technology has become a part of the lineup of many opticians across the world. Until now the materials available to make durable and long-lasting glasses have been limited to glasses with matt solid coloured surfaces. But now Danish eyewear brand, Monoqool, adds another dimension to 3D printing: semi-transparent 3D printed glasses. Not only a new take on 3D printed glasses, but it also features an environmentally friendly manufacturing process – the LIQUID 3D Technology™ process.

90% reduction in energy consumption

The LIQUID 3D Technology™ provides one of the most sustainable manufacturing processes in the eyewear field. A low-temperature process combined with ultra-fast printing means that very little energy is consumed compared to conventional SLS 3D printing. In fact, 90% less energy is used during manufacturing with the Liquid 3D process, resulting in a dramatically reduced Co2 footprint. And compared to the process of making traditional acetate glasses the CO2 reduction is even higher. A positive step in relation to reducing the environmental impact of eyeglasses in general.

[sf id=29 layout=1]

Translucent 3D printing – LIQUID 3D Technology™

Translucent 3D printing has long been on the wish list for Monoqool, and the new technology and new materials bring new possibilities to the table. More colourful glasses combined with design freedom allow the company to play with eyewear shapes, 3-dimensional details, and eyewear hinges only possible in 3D printing. The new translucent glasses feature a clever screwless hinge system, multi-adjustable temples, and nose pads making the glasses very easy for the optician to fit to the consumer. The frames are made with non-slip end tips and nose pads, making sure that the glasses don’t slide down the nose as many users of acetate glasses are often experiencing. In 2019, Monoqool launched the world’s first 3D-printed glasses in a plant-based material – castor beans. Now the company takes another major step towards an even more sustainable manufacturing process.

About Monoqool:

It’s in the DNA of Monoqool to break new ground and use new technologies & materials to create innovative eyewear. Bringing the wearer ultimate comfort is top of their agenda. Their ultra-thin frames are all lightweight, have no screws, and are easy to adjust.

The simplest ideas are often the hardest to get. The solution that makes you think: Why didn’t I think about that? Such an idea is a result of eliminating all unnecessary elements. That’s what they strive for. Every day.

Working out of the Danstruplund Estate in the midst of beautiful nature North of Copenhagen, their design team escapes the clutter and chaos often associated with modern lifestyle. Here they free their minds and get back to their roots, their Danish design heritage.

Read more about this brand on TEF Magazine or visit their website.

Sign up for our newsletter and stay up to date on amazing independent eyewear